By the way have I ever said how much I dislike painting projects? Not for the reason you would think. Not because it hides the wood. It does do that but because I just really don't like painting. I would rather spend days sanding then even a day painting. This project was hours of painting. The final product looks good but man do I dislike painting things when there are multiple surfaces to paint and it is not just cover this with paint.

I decided on designing my own pattern for this years gift. I also decided to cut with an angle to drop the letter into it. It is very interesting to cut at an angle. You start with doing all the 90°. Then if you want the letters to drop in you need to cut the cut at this type of angle \. To be exact what I used was 4° off of 90°. So depending on if your blade tilts or the table tilts that is what determines which way +4° or -4°. I used a Flying Dutchman 5 ultra reverse blade so with the kerf of that bade and 4° tilt I get about 3/16" inset. If I went the other way I would get a 3/16" outset. So I wanted to to drop. The main reason is then I was able to sand down the letter backs sticking out the back to make them flush with the board. To drop you must remember that the cut needs to be wider at the top with the kerf cut it will cause the shape to fall in and eventual jam in place. You just put glue on it and push the shape in and let it dry.

Here is the pattern I created. You can freely use this pattern. The only restrictions I place on this is that you can not sell the pattern. You can give the pattern away you just can't sell the pattern. You can always sell the item you make if that is what you wan to do.

I have two versions of the pattern. One that is the full pattern and one that is the pattern split in two pieces. This is 14 3/4 wide so you will need to piece it together or print it to fit on a legal size sheet of paper. I made the outlines red simply because I like to follow red rather then black lines. As I get older I lose the blade in black. While I can see it clearly against a red background. You cut the outside at 90 and cut the letters at either 94 or 86 depending on if your table tilts or the blade tilts. Also depending on if you want outset or inset letters

You also need to remember when you drill your holes to drill them at the same angle.

Here are the patterns

Full

Two halves

Here is the video of my cutting one of these.

Some single shots of the project

The frame and letters v\cut out with the pattern still attached

All cut and pattern removed. I numbed the pieces not so much to tell where they go but so when I was painting them I would paint the proper side. You would be surprised to know how often I would have the wrong side facing me.

All glued up and mostly painted. Sanding down the letters now. The one in the back sis all sanded down while the one in front is up next to sand.

I used a belt sander to take the bulk off then I used a random orbit sander to do the final bit to smoth it out.

For the final look at the front and back of a couple of the finished ones.

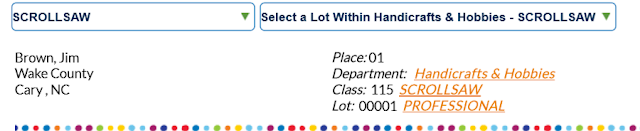

Jim